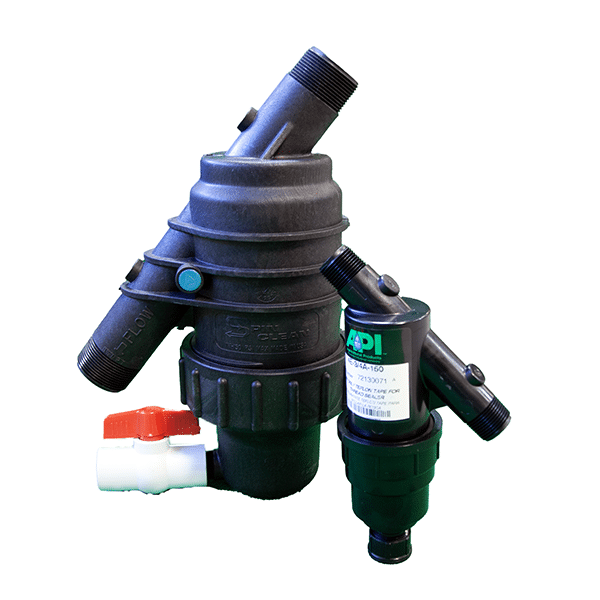

When water enters the filter the Spin Plate increases velocity and directs the flow into multiple spiral jets. The spiral action uses centrifugal force to separate heavy and medium weight particles to the outer edge of the filter barrel and down along the inside of the screen into the debris basin. The downward spiral flow action also picks up lighter particles too large to pass through the screen forcing them down into the debris basin. Thus, providing vortex separation and decreasing or eliminating the need for manual screen cleaning.

Available for multiple size Spin Clean Filters. The spin plates are needed for this unique Spin Clean® action to keep the screen clean, during operation.

SEE CHART BELOW FOR SPIN CLEAN® SPIN PLATES

| API 72140001 | 2 Holes for 3/4-inch, Range: 9 GPM (Green in color) | |

| API 72140002 | 2 Holes for 1-inch, Range: 18 GPM (Black in color) | |

| API 72140013 | 4 Holes for 1 1/2″ or 2″ Filter, Range: 44-55 GPM | |

| API 12140029 | 4 HOLE PLATE FOR 1 1/2-inch or 2-inch Filter, Range: 90-110 GPM |

Operation: Incoming unfiltered water from the inlet is forced though the nozzles of a stationary spin plate at the top of the filter screen element. These nozzles blast water across the inside screen surface, continuously sweeping the screen clean, spinning debris toward the basin where it is collected.

Each filter model is designed to self-clean over a flow range corresponding to pressure differentials between the inlet and outlet of the filter of from 5-8 psi.As long as the flow through the filter is sufficient to produce these pressure differentials, a strong self-cleaning action will be maintained. These flow ranges are shown for each filter model in the Flow Range charts.

These pressure differentials are critical for the filter to run long periods without maintenance. Operating the filter at less than the minimum pressure differential will reduce the cleaning action resulting in more frequent screen clogging and disassembly to remove and clean the screen.nnnn4E Spin Clean models usually require only periodic flushing of contaminants from the drain basin. With higher loading of contaminants, it may be necessary to flush more frequently or on a continuous basis with a small flow of water.