$35.00 – $38.00

1 1/2″ Pressure Regulators by Netafim

Select options This product has multiple variants. The options may be chosen on the product page

$99.00 – $169.00

1.0 Mil BLACK – Embossed Plastic Mulch in various widths

Select options This product has multiple variants. The options may be chosen on the product page

$135.00 – $211.00

1.0 Mil White on Black Embossed Plastic Mulch

Select options This product has multiple variants. The options may be chosen on the product page

$169.00 – $208.00

1.25 Mil BLACK Embossed Plastic Mulch

Select options This product has multiple variants. The options may be chosen on the product page

$221.00 – $257.00

1.25 Mil WHITE ON BLACK Embossed Plastic Mulch

Select options This product has multiple variants. The options may be chosen on the product page

$207.00 – $277.00

1.5 Mil High UV BLACK Embossed Plastic Mulch

Select options This product has multiple variants. The options may be chosen on the product page

$156.00 – $179.00

1″ Poly Tubing, 660 foot roll- Only Ships Freight

Select options This product has multiple variants. The options may be chosen on the product page

$6.95 – $17.00

1/2-inch Impact Full Circle Sprinkler by Netafim #DNET 8550

Select options This product has multiple variants. The options may be chosen on the product page

$56.00 – $145.00

1/2″ Poly Tubing in Black or White. #POL005 (500′ or 1000′ rolls)

Select options This product has multiple variants. The options may be chosen on the product page

$175.00

10 Mil Medium Weight AquaTraxx Drip Tape by Toro (6,000′ Roll)

Select options This product has multiple variants. The options may be chosen on the product page

$170.00

10 Mil T-Tape, Medium Weight Drip Tape (6,000′ Rolls)

Select options This product has multiple variants. The options may be chosen on the product page

$17.00 – $20.00

100 Feet of 1/4″ Drip-In Micro-Line Tubing. 6″ or 12″ spacing

Select options This product has multiple variants. The options may be chosen on the product page

$19.00 – $39.00

100 foot rolls. 1/2-inch, 3/4-inch or 1-inch in Black or White Poly Tubing

Select options This product has multiple variants. The options may be chosen on the product page

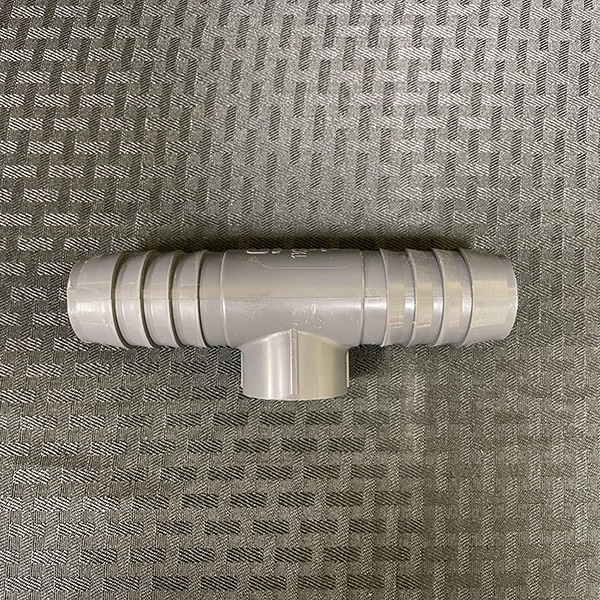

$3.95

1401 Insert Reducing Tee, PVC Barbed (Insert x Insert x Insert)

Select options This product has multiple variants. The options may be chosen on the product page

$1.44 – $51.50

1401 Insert Tee, PVC Barbed (Insert x Insert x Insert)

Select options This product has multiple variants. The options may be chosen on the product page